Why Every Café Needs an Industrial Coffee Grinder

Why Every Café Needs an Industrial Coffee Grinder

Blog Article

Industrial Coffee Mill Overview: Boost Performance and Quality

In the competitive landscape of coffee production, choosing the right commercial coffee mill plays an essential role in improving both efficiency and item top quality. Comprehending the subtleties of various grinder kinds and key attributes-- such as customizable grind setups and durable building-- can dramatically influence the final taste profile of the coffee. Additionally, the optimization of the grinding procedure, coupled with persistent upkeep, is essential for sustaining efficiency with time. As we check out these vital elements, it becomes noticeable that the implications extend past simple devices selection, influencing overall company success in methods that call for closer exam.

Recognizing Mill Kinds

When choosing an industrial coffee grinder, understanding the various kinds readily available is critical for maximizing both taste extraction and operational performance. The 2 key sorts of grinders are blade mills and burr mills. Blade grinders utilize sharp blades that cut coffee beans right into inconsistent sizes, leading to uneven extraction and potentially unwanted tastes. While blade grinders are often extra cost effective and appropriate for small operations, they are usually not recommended for commercial usage.

Eventually, picking the best kind of mill is indispensable to preserving quality and effectiveness in coffee manufacturing, making it crucial for businesses to buy high-quality burr grinders for ideal outcomes.

Key Functions to Take Into Consideration

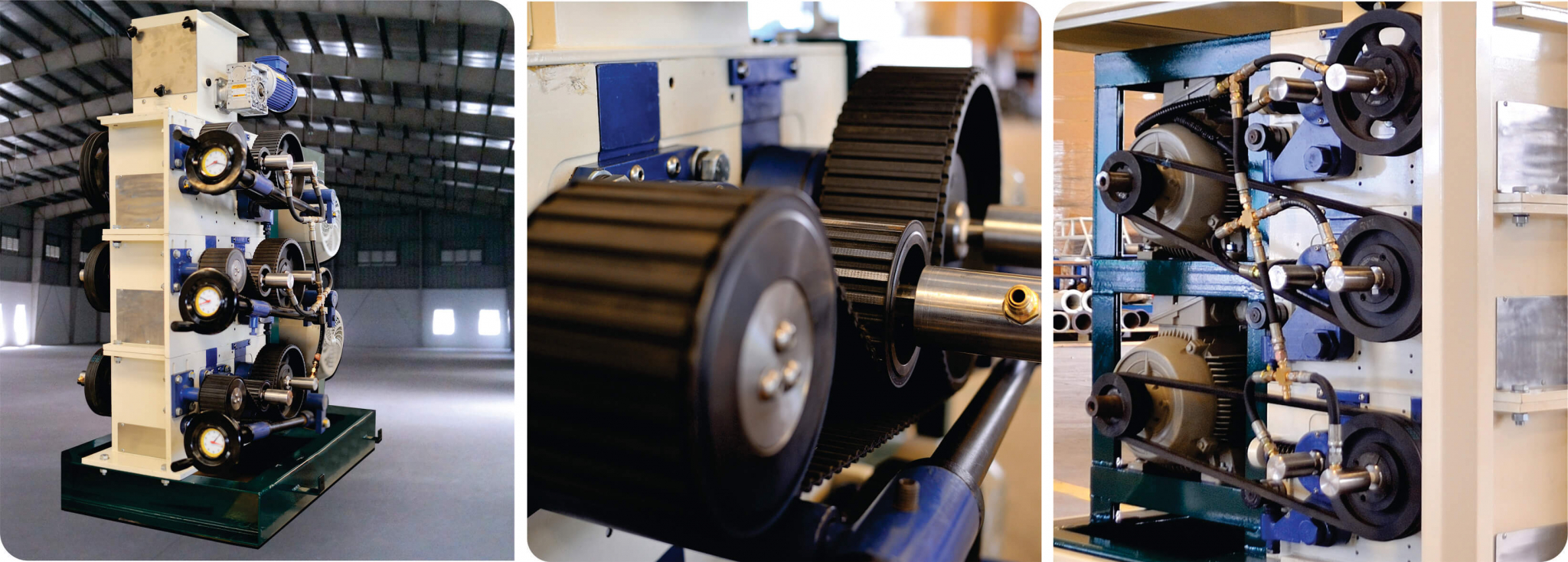

Selecting an industrial coffee mill calls for careful consideration of a number of vital features that can substantially affect both performance and the overall coffee experience. One of the main facets to review is the grinding mechanism. Burr grinders are typically preferred over blade mills, as they offer a constant work dimension, which is crucial for optimal extraction and flavor.

One more important function is the grinder's capacity. A versatile mill with multiple setups permits you to customize the work size to various brewing methods, improving the coffee's flavor profile.

The building material also plays a duty in durability and upkeep. Stainless-steel elements typically provide longevity and are easier to cleanse, which is necessary for preserving hygiene criteria. Assess the grinder's noise degree, especially in an active coffee shop or production setting, where excessive sound can be disruptive. Spending in a grinder that stabilizes these functions can greatly boost both operational performance and the quality of the coffee offered.

Optimizing Grinding Refine

To achieve the most effective cause coffee preparation, maximizing the grinding process is necessary. The grind size dramatically affects removal, taste, and general top quality of the brewed coffee. Different developing methods require certain work sizes; for example, espresso requires a great work, while French press necessitates a rugged appearance. Understanding the relationship between work dimension and developing approach is the initial step in optimization.

Additionally, keeping an eye on the grinding rate can maximize the procedure. Slower grinding commonly generates much less warmth, maintaining fragile tastes and fragrances. Alternatively, much faster grinding might create too much warm, negatively affecting the coffee's top quality.

Upkeep and Treatment Tips

Proper maintenance and treatment of industrial coffee grinders are important for making certain optimum performance and long life. Normal cleansing is the foundation of maintenance; residue accumulation can influence flavor and grinding efficiency. It is recommended to cleanse More Bonuses the mill after each usage, wiping down the exterior and removing any kind of coffee grounds from the burrs.

Additionally, check the grinding burrs for deterioration. Boring burrs can compromise grind uniformity, so they ought to be replaced as essential. Industrial Coffee Grinder. Occasionally calibrating the mill is likewise crucial, as this keeps the desired work dimension for various developing methods

Lubrication of relocating parts need to be executed according to the producer's specs, as this reduces friction and prolongs the life of the equipment. It is necessary to use food-grade lubricants to make certain safety and security and conformity with health and wellness regulations.

Lastly, keep the mill in a dry and steady environment to stop rust and deterioration. By adhering to these upkeep and treatment ideas, operators can boost the efficiency of their commercial coffee grinders while ensuring top notch outcome and prolonged operational life.

Return on Financial Investment Evaluation

Assessing the return on investment (ROI) for industrial coffee grinders is critical for businesses seeking to enhance their coffee manufacturing capacities. An extensive ROI evaluation helps determine the monetary feasibility of purchasing high-grade grinders, allowing businesses to evaluate the preliminary expenses against prospective gains.

To carry out a detailed ROI evaluation, services need to take into consideration numerous vital factors. First, assess the purchase price of the mill, consisting of installment and any kind of essential alterations to existing straight from the source framework. Next, compute functional prices, including energy usage, upkeep expenditures, and labor performance improvements. High-performance grinders typically cause minimized grinding time and boosted throughput, that site which can substantially boost performance.

Furthermore, think about the effect on item quality. Industrial Coffee Grinder. Superior mills yield an even more constant grind size, which can enhance flavor accounts and client complete satisfaction, eventually driving sales. By boosting the quality of the final item, businesses can validate greater rates, resulting in increased income

Verdict

In summary, a commercial coffee mill plays a critical duty in boosting both efficiency and product quality within coffee manufacturing. By selecting top quality burr grinders equipped with important features such as adjustable work settings and sturdy building, organizations can ensure ideal taste extraction. Moreover, normal upkeep is essential for maintaining mill efficiency and maximizing customer fulfillment. Inevitably, the strategic investment in a reputable mill adds dramatically to improved revenue and competitiveness in the coffee industry.

In the affordable landscape of coffee manufacturing, choosing the best commercial coffee mill plays a critical duty in improving both efficiency and item top quality. The 2 main types of mills are blade mills and burr grinders. Within the burr grinder group, there are level burr grinders and conelike burr mills, each with its advantages. Burr grinders are usually liked over blade grinders, as they provide a regular work size, which is crucial for optimum removal and flavor.

In recap, an industrial coffee grinder plays a crucial function in enhancing both performance and product quality within coffee manufacturing.

Report this page